Aging simulation for automotive product development

Reliable and durable electronics are essential for many applications. This is all the more true for safety-critical features such as in automobiles or industrial automation. If semiconductor manufacturers want to offer technologies for durable components in these application fields, they therefore need to demonstrate that individual transistors can perform their task perfectly under defined operating conditions even after a long time.

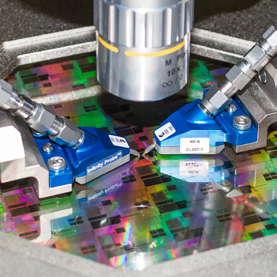

That is why the primary focus during the joint work of Fraunhofer IIS / EAS with semiconductor manufacturer LFoundry was on models for the 150 nm technology. These models are integrated into what are known as “process design kits” (PDK) to allow aging simulations. Using PDKs, customers are able to bring their own developments to the market more quickly on the basis of LFoundry technologies. What is more, the design flow with regard to the highest quality requirements of automotive product development will receive the best possible support. The researchers at Fraunhofer IIS / EAS primarily analyzed the effects of different wear-out mechanisms on components within the LFoundry technology.

The expanded PDK was made available in December 2018. Furthermore, together with Fraunhofer, additional optimizations of the proof of reliability are planned. For example, in the future even more precise simulation results will be obtained from advanced aging models so that the electronics can also be used more specifically in new application areas.

Last modified: