Sensors and Sensor Systems

Artificial intelligence optimizes production processes

Together with partners from industry and research, Fraunhofer IIS develops holistic AI solutions for Industry 4.0.

Microelectronics, when combined with sensor technology and software, can be used to digitize production processes and operating procedures in Industry 4.0, thus making them more efficient. However, currently available electronic systems for data acquisition and signal processing are not optimized for this application area. Especially digital signal processors (DSP) or field-programmable gate arrays (FPGA), which are suitable for the use of universal AI algorithms, are not only expensive – they also exceed the space and energy requirements of many sensors commonly used in Industry 4.0. Direct replacement of individual elements is therefore not possible.

Combination of hardware and software

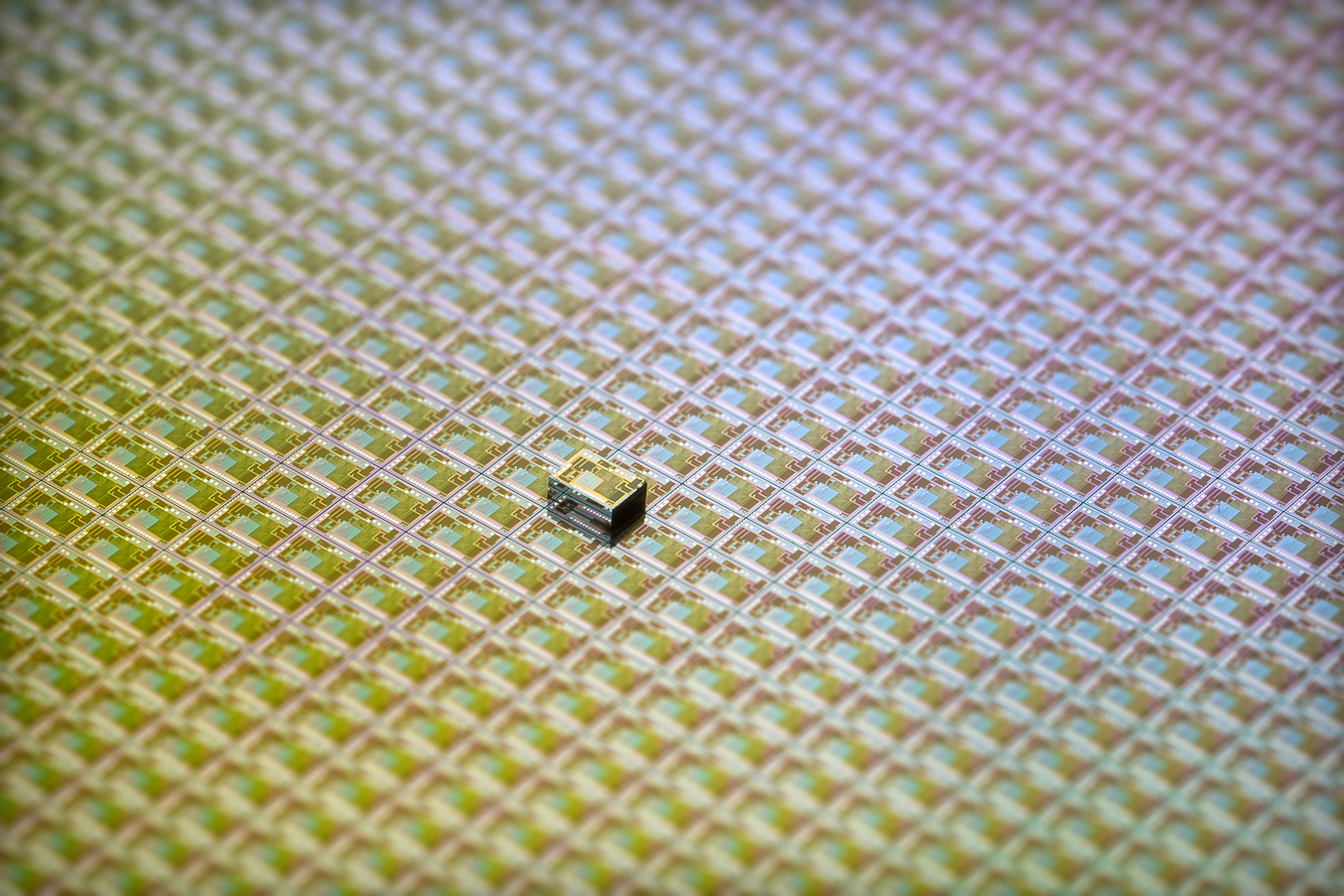

The "KI-Predict" project follows a holistic approach that combines AI methods with specially optimized integrated hardware. This interconnection of hardware and software enables intelligent process monitoring with data processing directly at the sensor. The sensor interface ASIC developed by Fraunhofer IIS is specifically designed for condition monitoring sensors and real-time process control. Features are captured energy-efficiently and also from high-frequency sensor signals. This enables decentralized analyses and forecasts with very low latency. The system can directly detect faulty sensors by interpreting anomalies.

Possible applications in the entire industry

The system is compatible with standard industrial interfaces and networks; the hardware can be automatically adapted to a wide range of applications. Industrial partners can thus increase the functional scope of their systems without additional infrastructure costs. By using more complex methods of AI and machine learning, the system can e. g. also be used to monitor plant status and product quality completely digitally. This optimizes operations, ensures the required product quality, and ultimately reduces costs. KI-Predict is funded by the German Federal Ministry of Education and Research (BMBF). The project runs from March 2020 to February 2023.

KI-Predict

Besides Fraunhofer IIS, the following partners are involved in KI-Predict:

- CANway technology GmbH

- GFE Schmalkalden e.V.

- ODION Ltd

- Sensitec GmbH, Lahnau

- SNR Wälzlager GmbH

- Saarland University

Last modified: