New evaluation criteria for heavy-wire bond contacts

For components in the micrometer range, engineers are placing their trust in new materials – particularly in the case of wire bond contacts that can be found in chips, electronic components and electrical connections, where they connect circuitry.

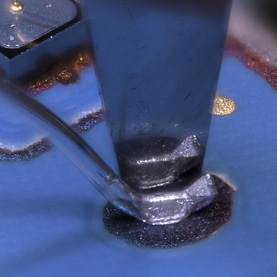

Heavy-wire bond technology is used for contacting power semiconductors in the areas of alternative energy generation and the electrification of vehicles. New types of aluminum wire materials and heavy copper wires with an aluminum coating are being used more and more: they are corrosion-resistant, ultra-high strength, and more heat-resistant, and they have a service life that is up to ten times longer.

To check the quality of the connection, mechanical tests such as pull and shear tests are carried out. The initial development and refinement of wire materials and changes to the mechanical properties exert additional effects on the test results. The interpretation of the test results and the evaluation criteria previously applied for classifying the bond quality need to be adapted. Within the current research project, entitled “Correlation of shear test results and reliability of fine-crystalline aluminum-based heavywire bond contacts”, Fraunhofer IMWS and Fraunhofer IZM are developing a fundamental knowledge base regarding the microstructure property relationships of the bond contacts. This is a requirement for the definition of generally applicable assessment and evaluation guidelines.

The project is being funded by Germany’s Federal Ministry of Education and Research (BMBF). The project executing organization is the German Federation of Industrial Research Associations (AiF).

Last modified: