Higher processor performance with microchannel coolers

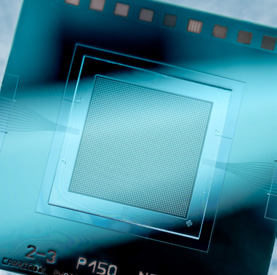

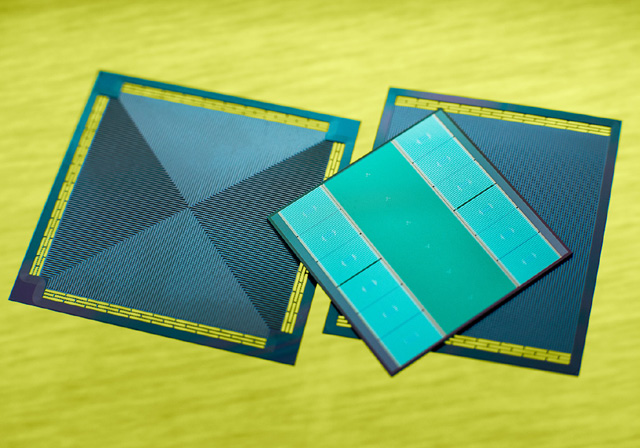

As part of the CarriCool project, Fraunhofer researchers have developed a new, effective cooling method. By integrating microchannels into the silicon interposer it is now possible to cool high-performance processors from the underside as well. Moreover, the scientists have integrated passive components for voltage regulators, photonic ICs, and optical waveguides into the interposer.

When processors get too hot, they reduce their clock rate and operating voltage. In order to protect the CPU and motherboard from heat damage, the processors either reduce their computing speed or even shut themselves off entirely. Effective cooling is thus an important factor in computing power. Up until now, cooling elements have been used to avoid overheating of the processors. At the same time, fans are used to cool the heat-sensitive components from above. A research team from the Fraunhofer Institute for Reliability and Microintegration IZM, in Berlin and Dresden, has now found a way to cool microchips from the top as well as from below using a liquid-based cooling system. The development was made as part of the CarriCool project under the aegis of IBM. For this purpose, microchannel structures with hermetically sealed vias are installed in the silicon interposer, which is located between the processor and the printed circuit board. The coolant is then pumped through the microchannels, channeling off the heat from the processor. This cooling system is considerably more effective than conventional solutions and demonstrably improves processor power.

Cooling near the computer core

The particular challenge was not only to integrate the small channels into the interposer, but also to hermetically seal them and thus to separate them from the electrical paths. The solution of the scientists: the interposer is made of two silicon plates. The horizontally extending cooling channels as well as the vertically extending channels for the electrical lines are incorporated in a complementary manner. In order to prevent contact between the water and the electrical vias, each individual contact is specially sealed. Up to now, the cooling structures have not been very close to the computer core itself. The closer you get to the heat source, the more effective the cooling. In high-performance computing in particular, the data rates are continuously increasing and this issue is becoming more important.

Additional optoelectronics for low-loss data transmission

As if the cooling system were not enough, the Fraunhofer researchers additionally integrated voltage regulators for the power supply as well as optoelectronic components for data transmission into the interposer. While the voltage regulator supplies the processor with the appropriate operating voltage, the optoelectronics converts electrical signals from the processor into light signals. As a result, even large amounts of data can be transmitted with low loss and high signal quality – in contrast to copper lines in which the data losses increase with growing data rate.

Last modified: