Sensors and Sensor Systems, Semiconductor based Technologies

New measuring method to regulate quick-curing processes

Adhesive methods are playing a more and more important role in industrial joining technology. In order to optimize and accelerate the curing process for an adhesive bond, the location of the adhesive is heated up. The temperature of the layer must be known so that the thermal curing can be regulated efficiently. Otherwise, there is a risk that the adhesive will become too hot and will be damaged. The surface temperature of the adherends is often measured pyrometrically. Correction factors are used to determine the temperature of the adhesive layer. The factors must be recalculated metrologically for each new usage case, however. Alternatively, thermal elements can be embedded into the adhesive location to allow direct measurement, which leads to increased costs in series production.

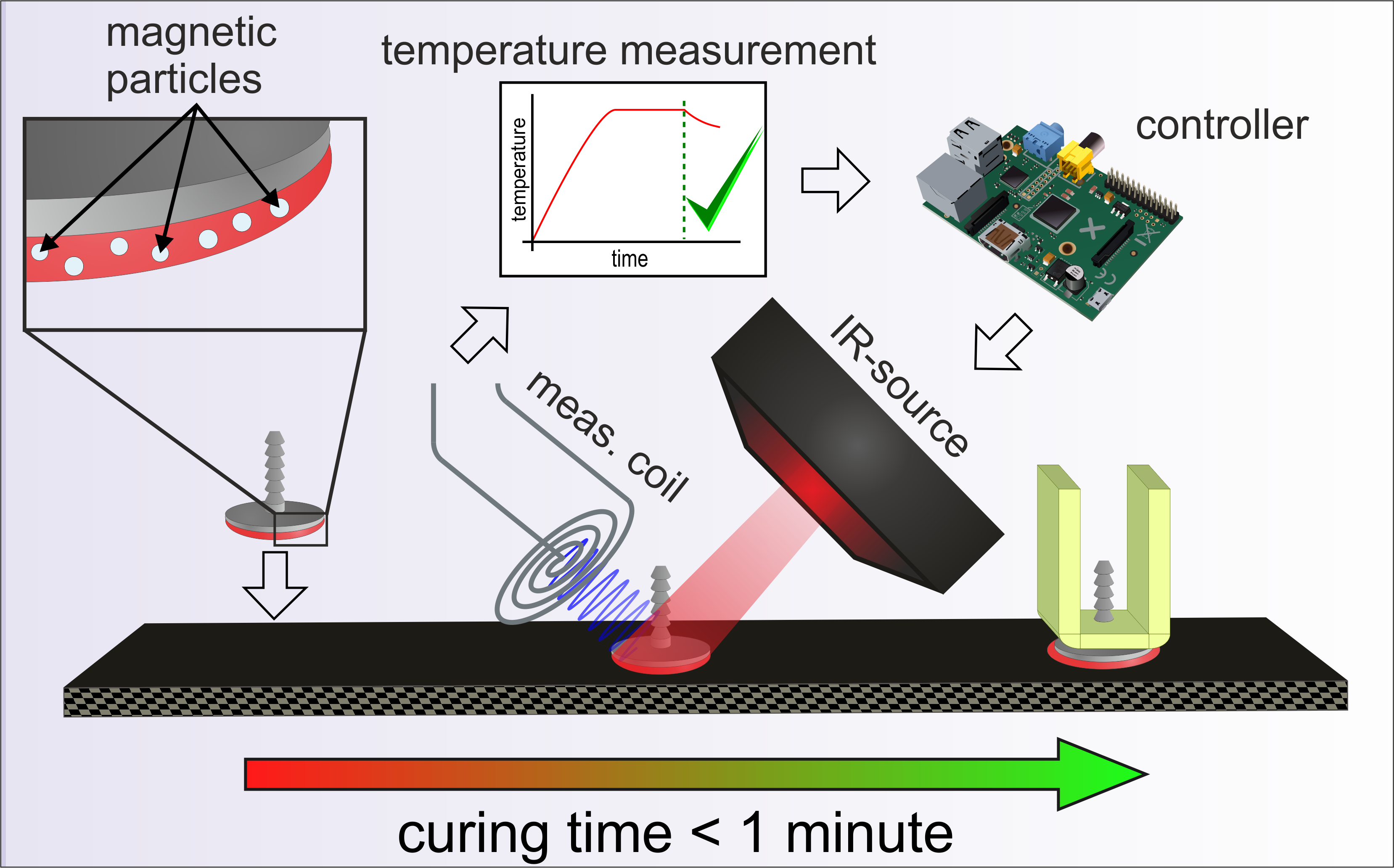

The Advanced System Engineering department at Fraunhofer ENAS, in cooperation with Fraunhofer IFAM, has developed an inductive measuring method for flexible, direct, and contactless measurement. This method allows the temperature of the adhesive layer itself to be recorded. To this end, magnetic particles are added to the adhesive. Above their Curie temperature, these sensor particles have a very temperature- dependent permeability that can be used to record the temperature of the adhesive layer. The induced change in permeability results in a change in inductance within a measurement coil. Thus, if the temperature is above the sensor particles’ Curie temperature, measuring the inductance means that the temperature of the adhesive layer can be determined.

By combining several sensor particles made of materials with different Curie temperatures, the measuring interval can be increased. In the current test set-up, two plastic adherends (made of e.g. GFRP or polyamide) can be glued together within 60 s. The samples offer adhesive strength comparable to that of samples cured using the conventional method (i.e. 30 min in a convection oven).

Last modified: