New CNT integration method

Fraunhofer ENAS has developed a modular method that overcomes previous hurdles in integrating carbon nanotubes (CNTs).

CNTs are a promising functional material in both nanoelectronics and sensoring. Integrating layers with vertically aligned CNTs can considerably improve the performance of energy storage systems and systems for heat management. Moreover, those layers are considered as a major element of various new sensor concepts in the field of tactile, gas or IR sensing. Widespread industrial use, however, has so far not come to fruition due to integration hurdles like the high process temperature, problems with contacting, and limited compatibility with overall system technology.

Methods without high-temperature processes

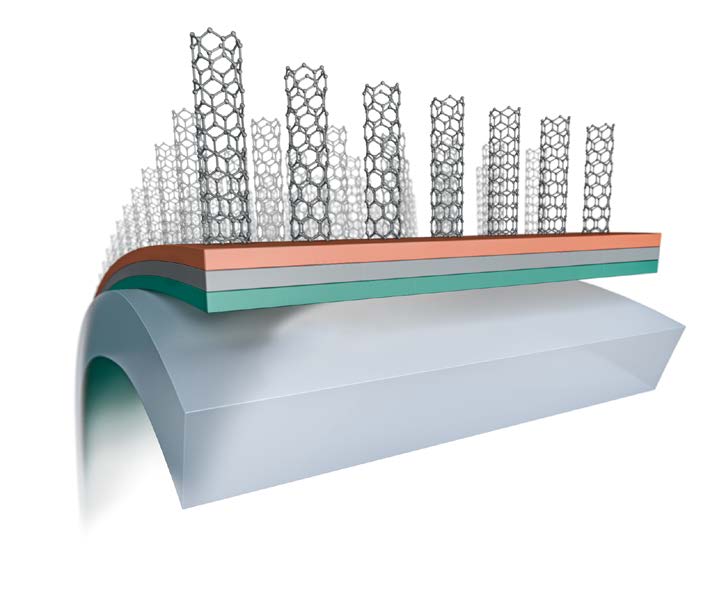

A new method gets around these challenges. A modular approach is taken in which the CNTs are first synthesized on a temporary substrate and are then transferred to the application substrate. To this end, various joining methods such as reactive joining, soldering, or gluing were developed and investigated.

This technology also opens up innovative integration scenarios: in contrast to printing processes and conventional synthesis processes, the CNTs are directly linked to a me- tallic layer on top of the CNT forest during synthesis – the ideal prerequisites for thermal and electrical interconnection. The selfforming CNT/metal heterostructure on the surface of the layers enables a broad spectrum of microtechnological follow-up processes for layer deposition, structuring, and lithography. In addition to supplemental contact forming processes, complex functional layer stacks of metals and insulators can also be set up before they are transferred to the target substrate.

Potential uses

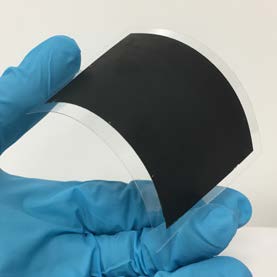

For demonstration purposes, plastic films were equipped with vertical CNTs including contact metal on the basis of which a flexible supercapacitor was set up. For the future, integrated energy storage modules – which would be of assistance with system-on-a-chip concepts – seem conceivable. The high degree of mechanical flexibility makes numerous applications in flexible electronics and sensoring a possibility. The modular method means that integrated nanostructures can achieve previously impossible performance levels. The development processes will also be considerably truncated, making them cheaper.

Last modified: