Sens-o-Spheres: mobile spheres as a measuring device

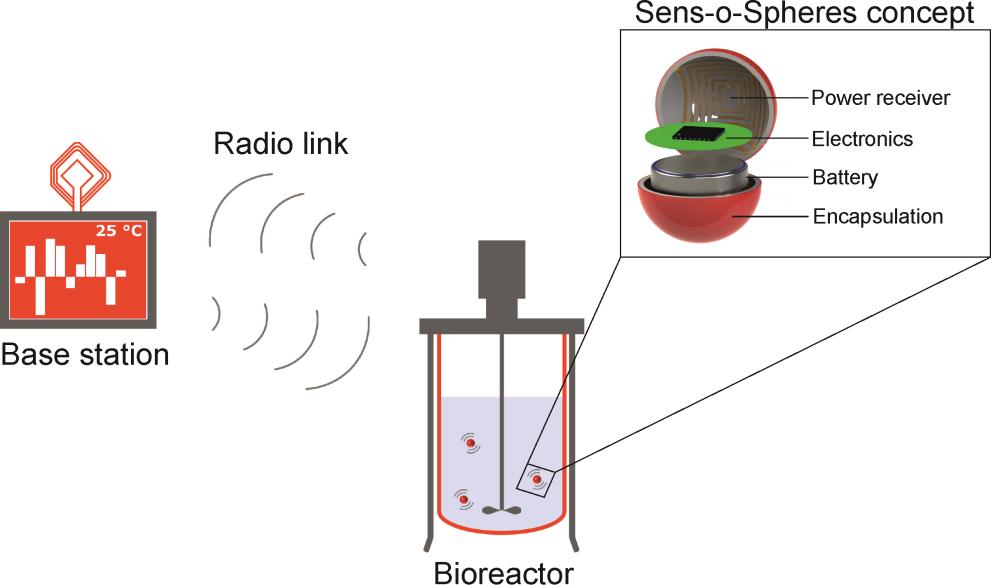

Fraunhofer ENAS, in conjunction with several partners, has developed a new type of measuring device for bioprocess engineering. Small spherical sensors with a diameter below 8 mm are directly brought into such processes instead of using conventional electrodes. This addresses the problems of classical measurement methods for biotechnological process engineering.

Process monitoring in bioreactors

Bioprocess engineering is essential to the development of pharmaceutical products, obtaining enzymes from renewable resources, and other biotechnological products. To achieve highly efficient, resource friendly and consistent biological target products, the exact knowledge of the data within its process is one of the main issues.

Innovative sensor spheres

The Sens-o-Spheres are about the size of a pea. Several of them are applied into the reactor at once, enabling a measuring resolution across the entire volume of the sample. Due to the spheres’ extremely small diameter of only 7.9 mm in combination with their special encapsulation, the procedure is minimally invasive. Furthermore, innovative bioreactors for new biotechnological production processes frequently make the installation of conventional probe systems impossible due to their design or dimensions, or else they exhibit inhomogeneities.

The spheres are equipped with advanced electronics for the measurement and the communication. The measured data is continuously transmitted to an external base station until the process is completed. Using this information, the base station can immediately influence the process. With a suitable encapsulation of the electronics, the measurement device is minimally invasive. In order to let the measurement device float freely in the fluid, its density has to be identical to the density of the medium itself. For a fully autarkical operation, a battery powers the electronic components. Using a specially developed wireless charging technology, the spheres are charged up again simultaneously after a process is completed.

Until now, the Sens-o-Spheres are equipped with a temperature sensor. In the future, however, the spheres will be combined with other typical measuring devices – for pH values or dissolved oxygen content, for example.

In current applications, typical bar shaped sensor electrodes are installed via a standard port into the bioreactor, representing a measured value only in one spot of the reactor. This can lead to false control settings and thus to suboptimal or unexpected outcomes. Furthermore, these classical measurement devices have an impact on the mixing procedure and the transport processes within the liquid. The necessary screw connections and cabling also considerably increase the work required. The Sens-o-Spheres address all of these problems, setting new standards for measuring technology.

The development of the Sens-o-Spheres involved, in addition to the Fraunhofer Institute for Electronic Nano Systems ENAS, the Technical University of Dresden and four partners from industry. The project is funded by Germany’s Federal Ministry of Education and Research (BMBF).

Last modified: