Fingerprint spectroscopy with varied use

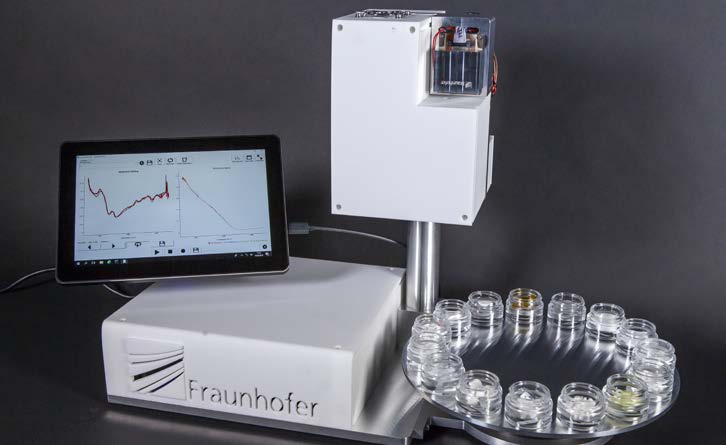

Fraunhofer IAF in Freiburg has developed a measurement system that enables the contactless identification of various substances in real time. It is perfect for use in the pharmaceutical, chemical, and food industries.

For pharmaceutical and food production, a continuous control of ingredients is indispensable. Previously, this would have been done via chromatography or infrared spectrometers. The measuring system developed at Fraunhofer IAF identifies substances based on their molecular composition within a few milliseconds, thus enabling quality control in real time.

Measuring procedure

The core of the system is a quantum cascade laser (QCL). The measurement principle is based on wavelength-selective illumination of the substance in the mid-infrared (IR) range. The intensity of the diffusely backscattered light as a function of the illumination wavelength allows to record absorption spectra of the substance. This is known as a spectral fingerprint, which is characteristic for the respective chemical substance. The measured spectral fingerprint is compared with a database containing a large number of spectra of chemical substances, thus enabling unambiguous identification.

The quantum cascade lasers provide an extremely broad spectral scan range and tuning speed combined with compact size. This is achieved by integrating the QCL in an external resonator that scans the entire spectral range of the QC laser chip in just 1 ms and records a thousand complete IR spectra per second.

Potential uses

The measuring system allows not only for contactless identification of a wide range of chemical and pharmaceutical substances in real time. It can also be used to continuously monitor chemical reaction processes. This means that previous complex measuring procedures in the laboratory can be replaced by inline real-time measurements during the ongoing production process.

In addition to the pharmaceutical, chemical, and food industries, quantum cascade lasers can be used in pollutant testing, medical diagnostics, and in the security and safety sector. Additionally, the compact design of the laser modules allows for the development of mobile, and even handheld, measuring systems.

Last modified: