Sensors and Sensor Systems

MIRPHAB: pilot line for customized spectroscopy solutions

Every chemical substance absorbs a very specific portion of infrared light. Like a fingerprint, this absorption spectrum can be used to identify a substance. The EU-funded project MIRPHAB is helping companies to set up specially customized sensors and measuring technology in the mid-infrared range (MIR).

If a company needs a sensor in order to identify a particular substance within the production process, there are often very specific requirements, starting with the materials to be identified, the number of sensors required and the speed of the production – and hence the measurement – process. An “off-the-shelf” solution rarely suffices and often several suppliers and technologies must be integrated in order to achieve an ideal solution.

This is where the European pilot line MIRPHAB (“Mid InfraRed PHotonics devices fABrication for chemical sensing and spectroscopic applications”) comes in. This pilot line is a cooperation of leading European research facilities and companies intended to offer customized solutions from a single supplier. Thanks to EU funding, these solutions are also suitable for early adopters.

Customized MIR laser source

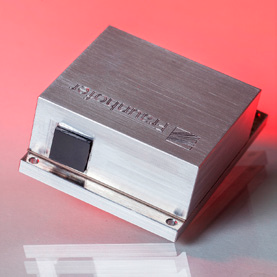

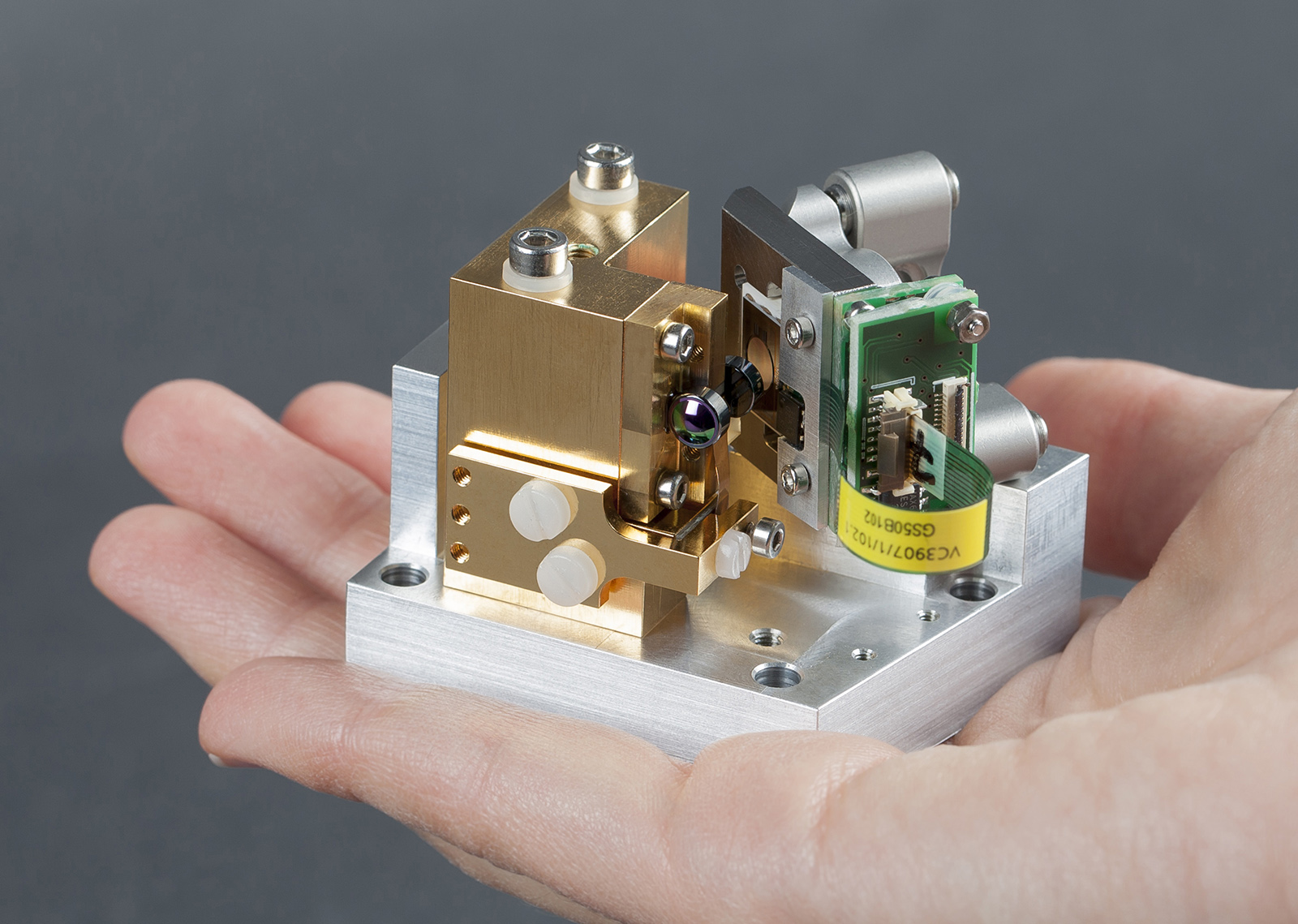

One central component of the MIRPHAB sensor solutions is jointly provided by the Fraunhofer Institute for Applied Solid State Physics IAF and the Fraunhofer Institute for Photonic Microsystems IPMS in the form of a spectrally tunable laser source that emits light within the mid-infrared wavelength range. Fraunhofer IAF’s contribution is quantum cascade laser technology. With this type of laser, the wavelength range of the light is very wide and can be customized during chip manufacture by means of the growth of the semiconductor material. In order to select a specific wavelength the laser uses an optical diffraction grating in an external resonator configuration to couple a part of the light back into the laser chip. A grating of this type is manufactured in a miniaturized form in MEMS (microelectro- mechanical system) technology at Fraunhofer IPMS. The oscillation of the grating continuously adjusts the wavelength of the laser. Since the grating oscillates at a frequency of up to 1 kHz, the wavelength of the laser source can be tuned up to a thousand times per second across a very wide spectral range. To make the manufacture of lasers and gratings more efficient and to optimize it for pilot series production, the Fraunhofer Institute for Production Technology IPT in Aachen is also involved in MIRPHAB. With its expertise, the institute is able to integrate the manufacture of the fast scanning MIR laser into processes suitable for industrial production.

Process analysis in real time

At the moment, many spectroscopy applications operate in the visible or near-infrared range and use relatively weak light sources. MIRPHAB offers solutions based on infrared semiconductor lasers. These have a much greater intensity and sensitivity and thus allow for new applications. With the MIR laser source, for example, up to 1000 spectra per second could be included, which would allow automatic monitoring and control of chemical reactions and biotechnological processes in real time. Processes such as these are used in the chemical industry, the health sector, and in forensics. In this way, MIRPHAB makes important contributions to the factory of the future and Industry 4.0.

About the project:

The following project partners work in the European pilot line MIRPHAB (“Mid InfraRed PHotonics devices fABrication for chemical sensing and spectroscopic applications”). CEA LETI (Coordinator) • Nanoplus • VIGO • IMEC • III-V-Lab • Alpes Lasers • Norsk Elektro Optikk • CSTG • Quantared • CSEM • IQE • Cascade Technologies • Bosch • mir- Sense • Phoenix • EPIC • Tematys • Fraunhofer Institute for Applied Solid State Physics IAF • Fraunhofer Institute for Photonic Microsystems IPMS • and the Fraunhofer Institute for Production Technology IPT

Last modified: