Exploiting minerals more efficiently with artificial intelligence

Fürth, Luleå, Berlin, Santiago de Chile: numerous ore deposits have diminishing concentrations of mineable ore. In order to access the hidden ore, the mining industry uses elaborate procedures that consume large amounts of energy and water. Fraunhofer IIS, together with three other partners, intends to use artificial intelligence and sensor fusion in order to analyze the concentration of valuable minerals as early as possible in the process and thereby conserve resources.

The overall objective of the REWO-SORT research project is the evaluation of the technical feasibility and development of an improved sorting technology for raw materials by means of a multimodal sensor data fusion of optical and X-ray technologies. The project will also examine the robustness of the methodology under variable geological conditions, such as different rock compositions.

Saving resources with sensor fusion

The early separation of low-value material in the process chain should not only increase the treatment efficiency, but also reduce the water and energy consumption in the subsequent process steps. The fusion of sensor technologies to be developed should provide constant and accurate monitoring of the mineralogy of the mined rock. What’s really remarkable is that the geological, mineralogical, rock mechanical, and metallurgical properties of the ore are determined directly while the rock material moves along a conveyor belt. This data will be automatically fed into geological 3D models in order to facilitate mine planning.

Complementing technologies

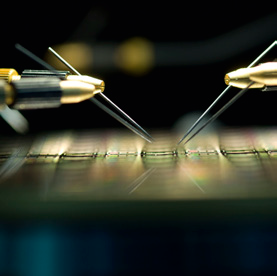

The combination of laser-induced plasma spectroscopy (LIBS) and multi-energy X-ray imaging (ME-XRT) is particularly promising, as the technologies complement each other very well in terms of their analytical performance: LIBS is able to provide an analysis of the chemical composition of the surface, whereas ME-XRT determines elementary information of the total object volume. “The technological convergence of these two sensor technologies will enable the extrapolation of precise surface information to the entire volume. This allows us to determine representative values for the entire ore. Adaptation to varying ore types and geological parameters will be done using artificial intelligence,” explains Dr. Markus Firsching, project manager at the Fraunhofer Institute for Integrated Circuits IIS.

About the project:

REWO-SORT is a joint project of Fraunhofer IIS, Luleå University of Technology in Sweden, the Secopta company, and the University of Chile. The work package of the German partners Secopta and Fraunhofer IIS is funded by the German Federal Ministry of Education and Research for a period of three years to the tune of around EUR 520,000.

Last modified: