Peak load reduction with cogeneration plant

Fraunhofer IISB has integrated a new cogeneration plant into its operating infrastructure. A special operating strategy was used to optimize the plant for peak load reduction.

In a combined heat and power unit (CHP), a generator is operated by a combustion engine. In order to maximize overall efficiency, the thermal energy generated is also used for heat supply. This makes cogeneration units suitable for heating private homes as well as for supplying electrical and thermal energy to energy-intensive industries.

Thermal energy storage systems optimize the running time

The new cogeneration plant at the Fraunhofer Institute for Integrated Systems and Device Technology IISB has also been expanded to include a thermal energy storage system. This allows the CHP unit to be operated largely independently of the current heat demand and thus more flexibly in terms of time. This maximizes the annual operating time and accelerates the cost compensation of the plant.

Peak shaving reduces electricity costs

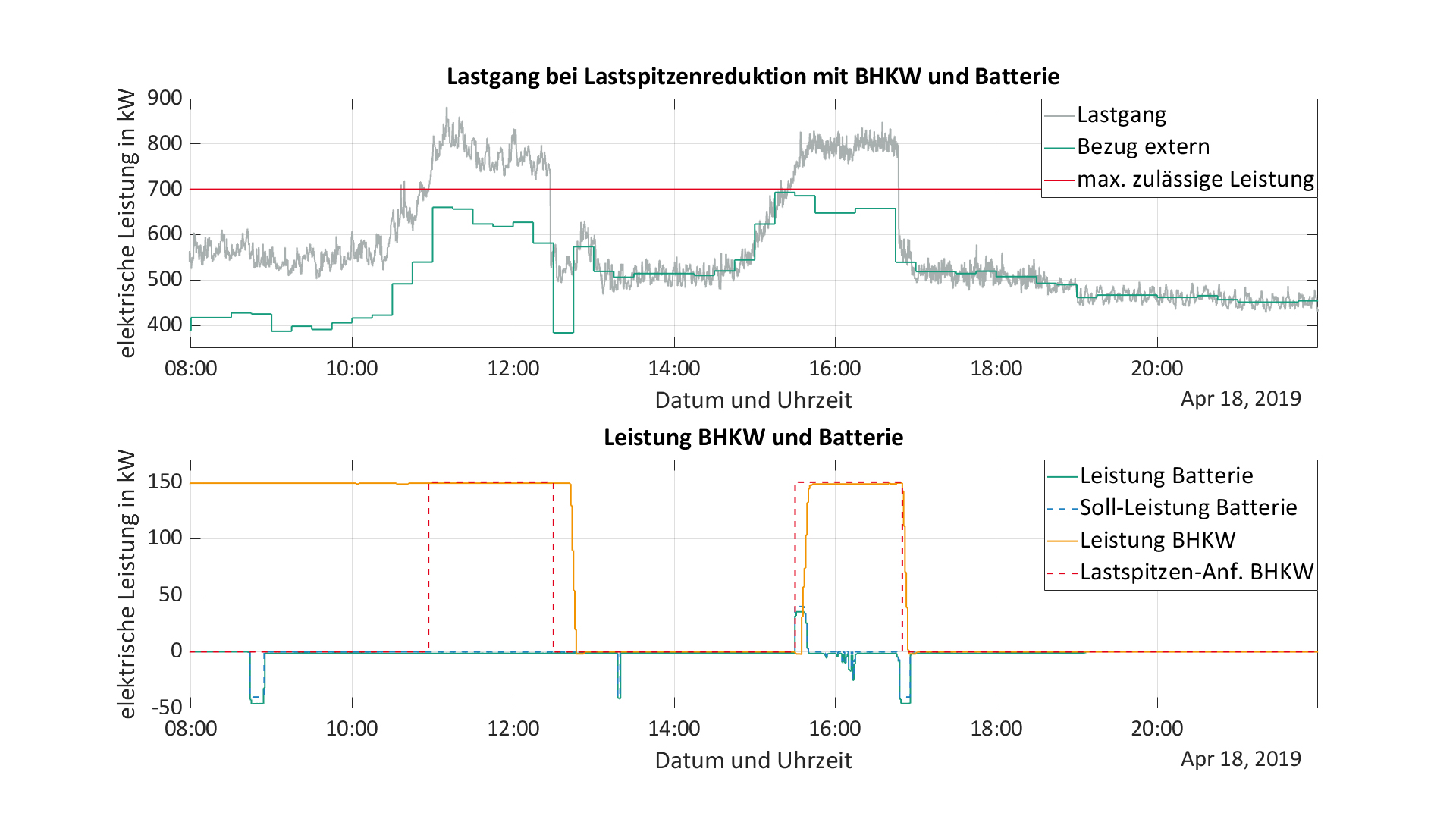

With a specially developed operating strategy for the cogeneration plant, which contains a finite state machine, the peak loads of the institute could be reduced by 20 %. Peak loads are temporary sharp increases in electricity consumption that often cause high energy costs. The reduction of peak loads (peak shaving) therefore allows to lower the resulting electrical energy costs.

Within the operating strategy, a predefined part of the capacity of the heat storage is reserved to enable the system to operate even when there is a high demand on electricity but a low heat demand. An additionally integrated battery system bridges the start-up time of the power plant from standby to full operation, supports the CHP during high peaks and shaves small peaks single-handedly.

The system is well suited for heat and power supply of medium-sized companies; the Fraunhofer IISB itself serves as a demonstration platform. Specially developed algorithms optimize the individual dimensioning of parameters of the CHP system and its components (e.g., electrical and thermal power, capacity of energy storage) and estimate the potential savings.

Last modified: