Safety and Security, Quality and Reliability

The last word … comes from Dr. Ines Veile

Dr. Veile, what are you working on at the moment?

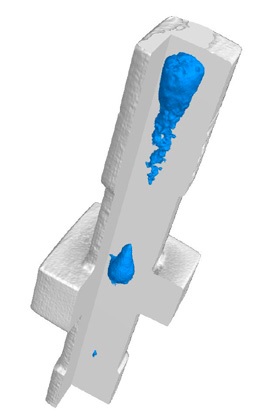

Together with colleagues, I am currently working on a project that examines the influence of manufacture-caused imperfections (i.e. interior defects) on the material behavior of cast steel. Due to its wide spectrum of mechanical properties and the design freedom it offers, cast steel is used for large, complex-shaped parts in shipbuilding. High safety standards must be adhered to. When working cast steel, however, it is almost impossible to avoid the occurrence of imperfections. The interior defects impair the local material properties, but this does not have to mean that the entire part is impaired. In order to investigate the influences in more detail, we characterize cast steel samples with various distributions of impurities. To this end, we use ultrasound and X-ray CT measurements. We have developed algorithms that can be used to represent and describe the defects found in three dimensions. This data is then used for a finite elements simulation. Together with colleagues from the Fraunhofer Institute for Mechanics of Materials IWM, we then attempt to predict how the imperfections found will affect the behavior of the material under static loads. At the same time, tests are carried out to compare the simulated breakage behavior with the real behavior.

Which of the projects being worked on by your colleagues in other Fraunhofer institutes interests you in particular?

I am generally interested in projects that meet the challenges that arise in the area of renewable energies. Rotor blades, for example, are still largely constructed by hand. This not only means relatively high production costs, it also leads to inconsistent quality. In the “Blade Maker” project, scientists at the Fraunhofer Institute for Wind Energy and Energy System Technology IWES Northwest are working on automation solutions in order to be able to manufacture these large components more cheaply, faster, and with better quality in the future.

What invention would you not like to do without in daily life?

A lot of my friends, acquaintances, and former colleagues are spread around the world. I could go without some things, but not without being able to chat with or write to distant friends regularly and with ease using the telephone and the Internet.

What do you wish you had more time for?

My biggest passion is definitely travel and everything connected to it: getting to know other people and cultures, discovering unknown landscapes, testing my own boundaries, and lots more beside. On more than one occasion, I have been lucky enough to be able to take a longer trip, and I fell in love with being able to travel without having a real time limit.

Let’s look into the future. What would you like to have achieved in five or ten years’ time?

In my experience, you can have as many specific plans as you like, but it usually turns out differently. That is why I got used to not making any too specific plans. Instead, I try to live and plan my life each day in such a way that I (hopefully!) won’t have anything to regret in five, ten, or even 25 years.

What song belongs to the “soundtrack” of your life?

Hmm... That’s a tough one. I like to listen to very different kinds of music. The first track that comes to mind is “I Lived” from One Republic. This song describes my attitude to life pretty well.

Last, but not least: can you tell us what motto you live by?

If your dreams don’t scare you, they are not big enough.

About Ines Veile:

Ines Veile studied geophysics at the University of Karlsruhe (now the Karlsruhe Institute for Technology, KIT) and received her degree in 2009. From 2009 to 2013, she wrote her doctoral thesis as part of a collaboration between KIT and the company Baker Hughes in the area of borehole geophysics. During this time, she worked on the development of a procedure that can map the structure of the vicinity of the borehole during the boring process. In 2014, she backpacked around Central America before starting in her position as a research associate at the Fraunhofer Institute for Nondestructive Testing IZFP in May 2015. Since December 2015, she has headed the “Ultrasound Processes for Materials Characterization” working group.

Last modified: