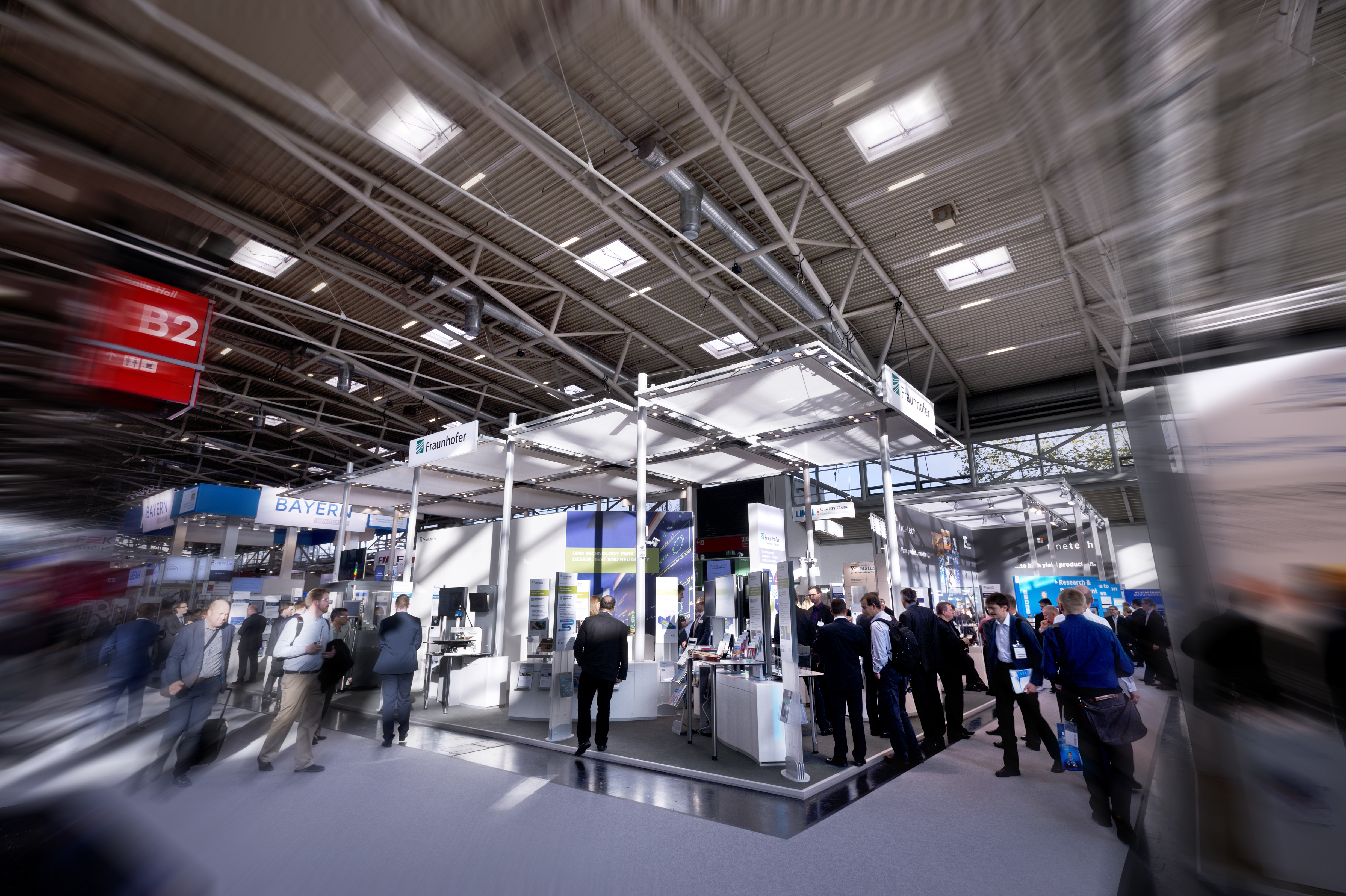

Hannover Messe 2018: Meet the “Research Fab Microelectronics Germany” at the joint Fraunhofer booth (hall 2, booth C22)

From April 23 to 27, seven Fraunhofer institutes within the Group for Microelectronics will present the “Research Fab Microelectronics Germany” (FMD) – the One-Stop-Shop for the complete micro and nanoelectronics value chain.

Within the Research Fab Microelectronics Germany, eleven institutes within the Fraunhofer Group for Microelectronics cooperate with the Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik and IHP GmbH – Innovations for High Performance Microelectronics in order to offer their customers comprehensive and simpler access to the next generation of technology. This new form of cooperation will make a major contribution to strengthening European industry’s competitiveness internationally. For the modernization and extension of their equipment the 13 research facilities receive around 350 million euros from the Federal Ministry of Education and Research.

Developments from an initial design to the finished system – all from a single supplier

As the largest cross-site R&D cooperation for micro and nanoelectronics in Europe, the FMD is able to offer its customers tailor-made technology and system developments from a single supplier. An additional benefit to FMD customers is its technological expertise, coordinated nationwide, in all areas of the value creation chain. The Research Fab Microelectronics Germany also has the largest systems pool for cross-technology research and development (silicon and compound semiconductors) – from material and process development right up to pilot manufacture exactly as ordered by the customer.

Seven project examples from within the FMD on site

Power electronics for vehicles: Fraunhofer IISB’s EMIo exhibit – a fully electronic motorcross motorcycle – is a demonstrator of the power electronic systems expertise to be found within the Research Fab Microelectronics Germany. The transmission, the battery modules, the cable harness, and much more were developed at Fraunhofer IISB in Erlangen. The EIMo demonstrates all the skills of the value creation chain offered by the institute when it comes to SiC power electronics: from SiC wafers and devices to packaging and compact high-performance converters.

Smart devices for machine tools: New challenges have to be faced in order to achieve process-controlled condition monitoring in barely accessible positions inside machines and systems. Therefore, the required infrastructure – miniaturized, cross-linked, and energy-efficient information and communication technologies – have to be integrated directly into the structures of drive mechanisms and tool components. To this end, the High Performance Center “Function Integration in Micro- and Nanoelectronics” and the participating Fraunhofer institutes demonstrate their expertise by designing, developing, and testing the integration of sensors and actuators in machines by means of a sensor ring on the example of a ball screw drive.

Examination of 3D printed high-frequency components: 3D printing of high-frequency structures is becoming more and more critical for the development of modern high-frequency systems. SAMMI (Stand Alone MilliMeter wave Imager) is a high-frequency screening system developed by Fraunhofer FHR, which can quickly and securely verifiy materials and their density distribution at various frequencies. SAMMI not only visualizes material gradients but can easily detect defects that occurred during the production process. The system has a compact structure, is easy to transport, and can be used in offices or laboratories, for example. At Hannover Messe, visitors will be able to scan material samples on site and verify the results.

Real-time layer thickness measurement with terahertz: Terahertz is a key technology for non-destructive material testing. Major advantages are examinations without physical contact and the analysis of complex systems with a low contrast range, in which established methods like ultrasonic usually fail. The Fraunhofer HHI has successfully developed a cost-efficient and compact measurement system that conducts real-time measurements of the thickness of multi-layer systems for the first time, an essential technology e.g. for lacquering lines. The new terahertz measurement system T-Sweeper will be presented live at the Hannover Messe.

Screening packaged goods in real time: Fraunhofer IAF's millimeter-wave radar makes the invisible visible. The technology can be used to screen packaged goods in real time – a step towards 100% control in logistics, production, and the security industry. Millimeter waves have the great advantage that they penetrate materials such as cardboard, plastic, or wood, thus showing the interior of the package. Fraunhofer IAF covers the entire value chain – from materials research, design, technology, and circuits to modules and systems.

Safe detection of obstacles for autonomous driving: The LiDAR (Light Detection and Ranging) camera and sensor system transmits pulsating laser beams that are reflected by an object’s surface. This allows obstacles on the road to be detected during autonomous driving, for example. Fraunhofer IMS will present a very special application of LiDAR technology: single-photon avalanche diodes (SPADs). SPAD devices are a hundred times more sensitive than, say, photodiodes that are integrated into smartphones. Both the sensor and the read-out electronics are installed on a single chip. This makes them particularly small and flat. Automobile manufacturers can thus easily fit them behind the windshield or the headlamps.

Air-coupled capacitive ultrasonic transducers for Industry 4.0: With the development of applications in Industry 4.0, smart security, and automotive, intelligent interactive systems are becoming indispensable for human-machine interaction. To allow, say, robots to perceive the distance to objects in their surroundings when moving or gripping, sensors are required. Proximity sensors allow dynamic processes in a room to be monitored in a contactless manner. At Hannover Messe, Fraunhofer IPMS will present the options offered by CMUTs (capacitive micro-mechanical ultrasonic transducers) for miniaturized near-field proximity detection. This technique uses ultrasound to determine the distance to an object within the near field.

Last modified: